Applicable industries of automatic pipe cutting machine

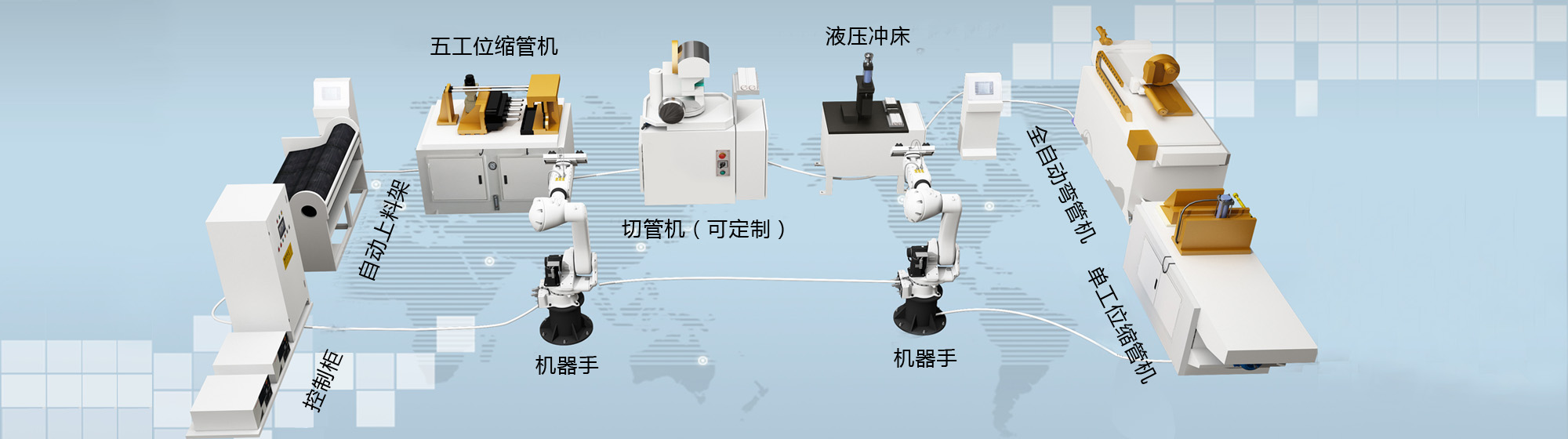

Product description of automatic pipe cutting machine: The automatic pipe cutting machine can automatically clamp, feed, feed, fixed-size setting, fixed-number shutdown and work measurement functions.

The counter can be set to cut the number of times, and it will stop automatically after cutting.

The main circuits of the two kinds of machinery work with the Japanese Mitsubishi PLC computer controller. The total counter can count the workload records of a day.

The total pressure, front, back, and pressure can be adjusted steplessly to ensure that the workpiece is not pinched and deformed.

The length of the pipe is accurate to plus or minus 0.02mm. The cut is shiny and has no burrs. The clamp can cut 1-28 pipes at a time. Automatic feeding, clamping and cutting system, accurate and fast feeding, cutting 10-20 times per minute.

Let's talk to you about the industries where the automatic pipe cutting machine is used: the application industries of the automatic pipe cutting machine include metal furniture manufacturing, auto parts manufacturing, fitness equipment manufacturing, hardware processing industry, pipe manufacturing, and shipbuilding. , Leisure and tourism outdoor products manufacturing industry, air-conditioning pipe fitting manufacturing industry, security door and security window manufacturing industry, bicycle and motorcycle manufacturing industry.

Automatic pipe cutting machine performance characteristics: 1. Bevel or mill groove. The machine head can be adjusted left and right for oblique cutting or slot milling. The angle is accurate and the pipe connection is perfect. 2. Accurate, fast and smooth. The cutting is accurate and the speed exceeds that of band saws and bow saws. At the same time, the cutting surface is smooth and does not generate heat, saving secondary processing. 3. Cooling system. Circulating cooling system, with extra large capacity oil storage barrel, to ensure the life of the saw blade, and the cutting surface is smooth. 4, no burrs, no dust. Bilateral two-way clamps make the workpiece stable, and the cut surface is smooth without burrs. Low noise and low pollution during sawing