Special Application Benders

Feeding is realized by a high-power servo motor driven by a Taiwan-made reducer to drive gears, and is supported by two sets of linear guides so that the feeding trolley runs more smoothly when moving forward and backward. The size of the push-bending radius is controlled by the angle of the bending arm, and the length of the push-bending arc is controlled by the length of the high-power servo motor.

Programmable arc lengths for large radiuses

Roll Bending spring back compensation settings

Special tube bending compensation and data storage fields

Low noise level with highest transmission performance

Description

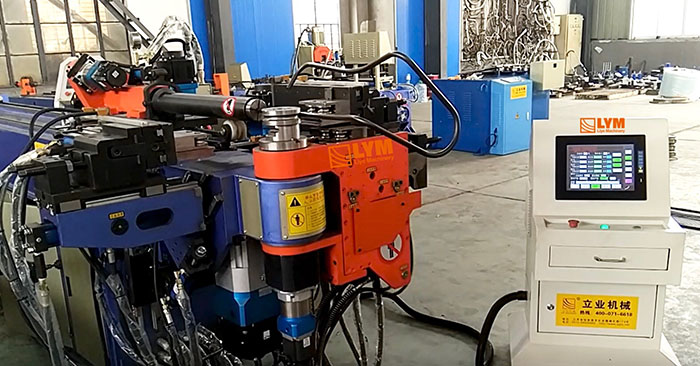

| Brand Name: | LYM |

| Model Number: | DW38CNC3A2S-T/DW38CNC6A-LRT/DW50CNC3A2S-T/DW75CNC5A3S-T |

| Type | CNC AUTOMATIC CONTROL |

| Certification: | CE/SGS/TUV/ISO |

| Place of Origin: | China |

| Application | Pipes or solid bars,various materials such as steel, stainless, aluminum and copper |

| Packaging Details | Packed in stretch film firstly,and then reinforced with plywood for outer packing |

PIPE BENDING MACHINE WITH PUSH-BENDING FUNCTION MAIN TECHNICAL SPECIFICATION

| Model | Bending Capacity (mm) | Axis | Videos(Click Here) |

| DW38CNC3A2S-T | OD 38.1 | 3 | |

| DW38CNC6A-LRT | OD 38.1 | 6 | |

| DW50CNC3A2S-T | OD 50.8 | 3 | |

| DW75CNC5A3S-T | OD 76.2 | 5 |