Multi-Stations Forming

The LYM SG Tube End Former Series is widely used in numerous end forming applications and industries, such as automotive exhausts, furniture, air conditioning, among others.

• The LYM SG pipe end forming machine is controlled by microcomputer and driven hydraulically. It applies Chinese character display and man-machine conversation operation, and can be operated manually or semi-automatically. One-point foot switch has two functions, startup and emergency stop.

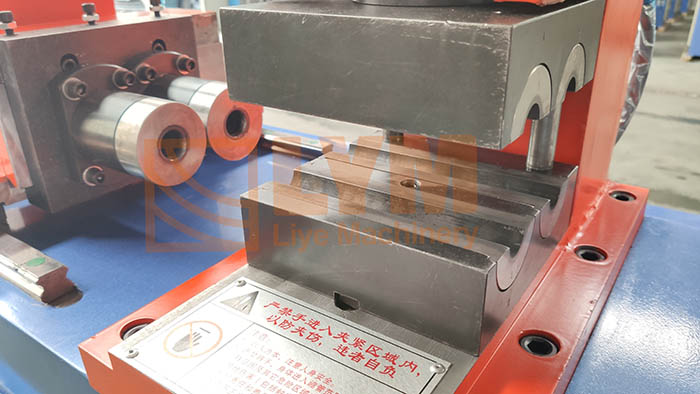

• With two-station arrangement..Applying linear guideway as the carrier, the product can ensure action without abrasion and ensure good repeatability.

• Processing shapes: convex-shaped, concavity-shaped, nodular shape, long partial shape, square shape, topological shape, oblique shape, V-shape, cracking type and flat type. The shape of the mould shall be subject to the object to be processed.

• The distance between two ends can be adjusted according to the length of tube. (limited to the double-end forming machine only)

• Single-end clamping or double-end clamping can be carried out according to length of the tube.

• Pipe end forming machine has characteristics including easy operation, stable performance, high work efficiency and high safety factor and it is an ideal device for tube processing industry.

Description

Brand Name: | LYM |

Model Number: | SG40/SG60/SG80/SG100/SG120/SG168 |

Type | Two-station forming |

Certification: | CE/SGS/TUV/ISO |

Place of Origin: | China |

Application | Pipes ,various materials such as steel, stainless |

Packaging Details | Packed in stretch film firstly,and then reinforced with plywood for outer packing |

• One pair of mould (Forming mould and clamping mould)

• One set of common tools

LYM Tube end forming machine is widely used in numerous end forming applications and industries, such as automotive exhausts, furniture, air conditioning, among others .

They can be with 2 operating stations to process operations on tube ends and are suitable for both straight and bent tubular parts.

PIPE END FORMING MACHINE MAIN TECHNICAL SPECIFICATION (TWO-STATION SERIES)

Model | Forming Capacity (mm) | Max Working process (mm) | Videos (Click Here) |

SG40 | OD 40 | 110 | |

SG60 | OD 60 | 130 | |

SG80 | OD 80 | 150 | |

SG100 | OD 100 | 150 | |

SG120 | OD 120 | 150 | |

SG168 | OD 168 | 150 |