Pipe Hole Punching(1-3 Cylinder)

• Touch Screen settings, CNC control system, precise servo motor positioning, module storage memory function.

• Structure:Steel plate welded structure,Hydraulic cylinder system

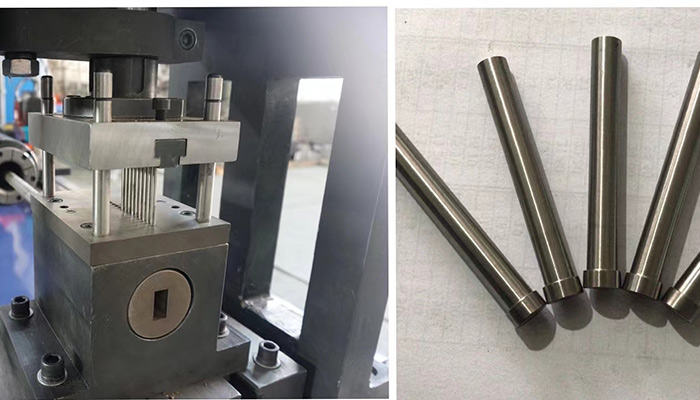

• Mould replacement: change the die easily without adjusting the dies to reduce the mould damage rate and pipe fittings rejection rate due to the dies setting error.

Skilled workers can change the mould within 10 minutes.

• Punching Category: 1.single hole punching;

2.Multi hole punching;

3.Isometric hole punching;

4.none- Isometric hole punching;

5.rotary punching.

• Hydraulic and Servo System.

• Step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration.

• When the oil cylinder is moving downward, the machine is designed with hydraulic difference driving loops rated at high or low RPM .it is also featured with high speed downward moving, low speed processing and hi-speed position resume .it is available to increase the formation stability of work pieces during puncturing .in addition to increasing the activation speed, it can effectively reduce HP load to save electrical energy.

• The electrical control system is designed with the human machine interface, range adjustment use digital scale, setting low speed position, floor level position, and operation precise and easy.

• Pipe feeding+Pipe rotation mode:Servo motor+reducer

11

Description

Brand Name: | LYM |

Model Number: | CK40CNC/CK60CNC/CK80CNC |

Type | AUTOMATIC CNC PUNCHING |

Certification: | CE/SGS/TUV/ISO |

Place of Origin: | China |

Application | Pipes,various materials such as steel, stainless |

Packaging Details | Packed in stretch film firstly,and then reinforced with plywood for outer packing |

At present, the traditional punching process on the pipe: making the mold, drilling with the drilling machine (see below picture), the production efficiency is low, the product quality is unstable, and the safety is not good.

By using our Liye company’s high-precision automatic multi-size hole pipe punching machine, we can punch out a variety of hole shapes at one time. The equipment uses the Japanese Mitsubishi servo system to control the movement and rotation of the pipe forwards and backwards, to achieve high-precision multi-size hole’s isometric ,unequal space, rotary punching. The quality stability of mass production is very high, the production efficiency is 5-6 times higher than that of the traditional process, and the safety is also greatly improved.