Vertical Type

LYM Vertical Series | Roll Forming

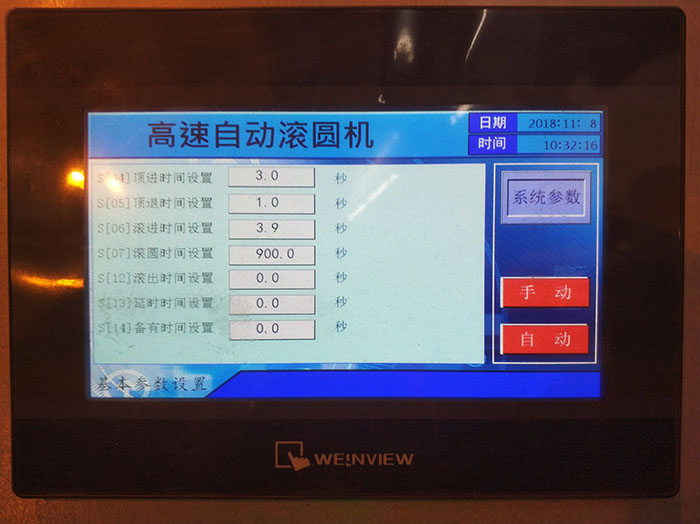

CNC control: LYM’s user-friendly CNC touch screen display enables full control of the automatic line in a synchronised and also in a autonomous way.

Versatility, diversity and production optimisation: Depending on the customer’s needs,LYM’s roll forming lines can be equipped with several different, interchangeable systems to easily meet specific requirements. Roller Bender with adjustable tooling to produce a variety of bespoke profiles with different dimensions make both efficient and versatile.

Cut-to-length: There is also an option to equip our roll forming machines with stationary or high speed cut-to-length systems.

If a reliable, effective and highly productionised roll forming is what you require then choose LYM

• LYM rolling section bender applies full mechanical drive, with compact structure and high reliability.

• Driven by three wheels, it will not slip easily and the thin-wall can be bent.

• The wheels at both sides are distributed asymmetrically, which shortens the linear segment.

• Parts can be fed at both sides of the wheel.

• The double foot switches are provided with emergency stop function, facilitating to operation.

• It has balanced drive. Adjusting the pressing can obtain circular arc or spiral shape with different curvature.

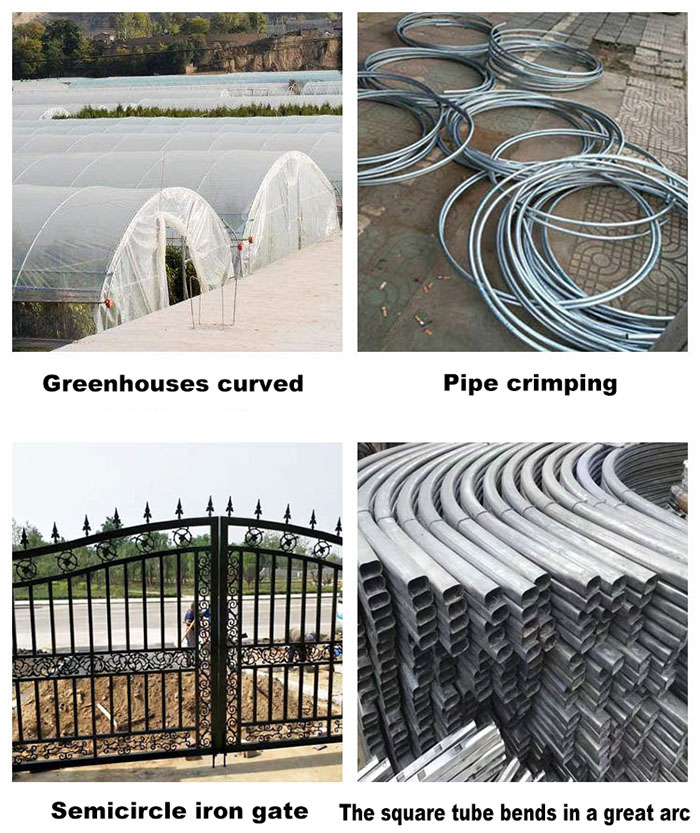

• Changing the groove shape of mould can process different metal profiles, such as angle steel, flat steel, round steel and other shaped cross section steel.

• Roll forming can bend profile with large radius, which prevents the disadvantage of especially big bending mould. It is a necessary supplement to single-end and double-end series tube bender.

• The roller machine can have medium and large volume production and can operate fast with high efficiency.

Description

Brand Name: | LYM |

Model Number: | GY38/GY50/GY80/GY120 |

Type | Vertical 7 rolls |

Certification: | CE/SGS/TUV/ISO |

Place of Origin: | China |

Application | Pipes or solid bars,various materials such as steel, stainless, aluminum and copper |

Packaging Details | Packed in stretch film firstly,and then reinforced with plywood for outer packing |

One set of common tool

Thesoftware allows programming up to multiple different parts in the same stock material, maximizing utilization of the complete tube.

ROLLING SECTION BENDING MACHINE MAIN TECHNICAL SPECIFICATION (VERTICAL SERIES)

Model | Bending Capacity (mm) | Min Bending Radius (mm) | Bending Speed (mm/s) | Videos (Click Here) |

GY38 | OD 38.1 | R200 | 80 | |

GY50 | OD 50.8 | R350 | 80 | |

GY80 | OD 80 | R550 | 80 | |

GY120 | OD 120 | R800 | 80 |